PRECISION. FLEXIBILITY. PUNCTUALITY.

Tailor-Made Sandwich Panels Manufacturing

About us

- 10,000 m² production facility

- State-of-the-art manufacturing technologies

- Over 70 skilled team members

- Strong environmental sustainability focus

- Committed to social responsibility

Palomar S.r.l. is an Italian company based in the heart of Tuscany, in the renowned Camper Valley, specialized in the production of high-quality custom sandwich panels. Founded in 2003 from the merger of three family-run businesses with a long-standing manufacturing tradition, Palomar combines artisanal expertise with cutting-edge production technologies. The result is a flexible and advanced production model, capable of meeting the most complex design, performance, and finishing requirements.

Thanks to a young and skilled team, that is constantly updating its expertise, the company has grown steadily, expanding its production facility to nearly 10,000 sqm and employing over 70 people.

Nowadays, Palomar stands out for the quality of its materials, attention to details, and a strong commitment to environmental and social sustainability. The company’s policies promote a responsible development, preserving the family values that inspired its foundation and continue to guide every strategic decision.

We design and manufacture sandwich panels with passion, precision, and vision.

Products

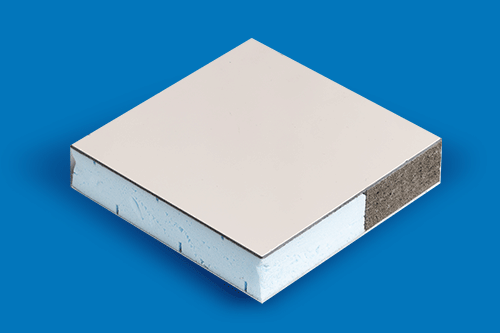

SANDWICH PANEL

- XPS insulation

- PVC perimeter reinforcements

- fabric covering

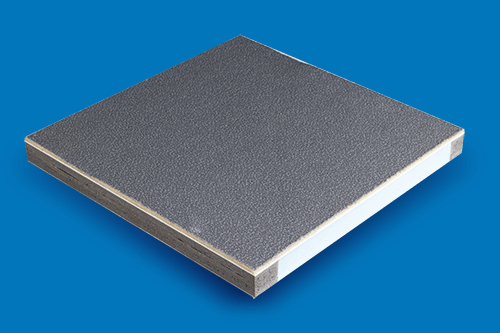

SANDWICH PANEL

- XPS insulation

- hidden internal perforated PVC reinforcements

- aluminum covering

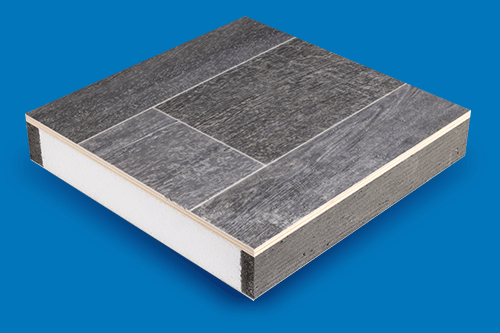

FLOOR SANDWICH PANEL

- EPS insulation

- PVC perimeter reinforcements

- raw poplar plywood and linoleum external finish, fiberglass underfloor covering

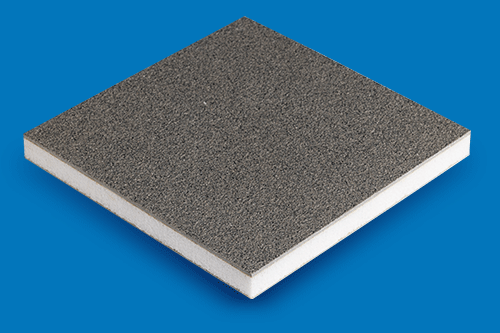

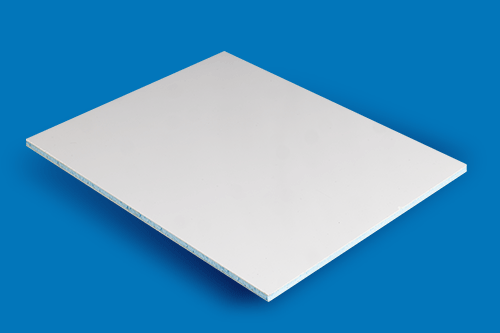

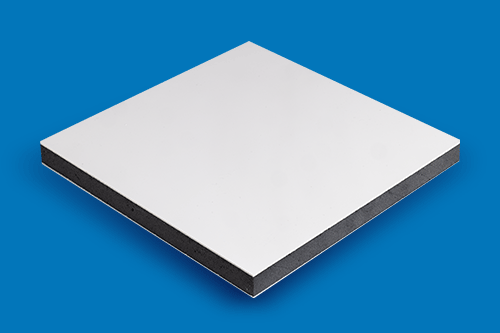

SANDWICH PANEL

- PVC core

- anti-slip fiberglass

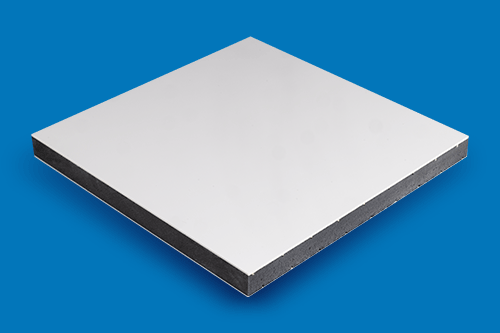

SANDWICH PANEL

- XPS insulation

- PVC inserts

- external aluminum finish

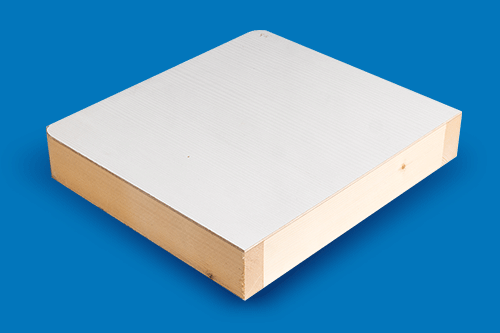

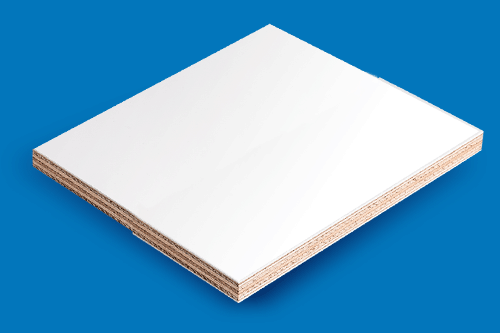

Sandwich wall panel for mobile homes

- EPS insulation

- wooden frame

- melamine-faced plywood external finish

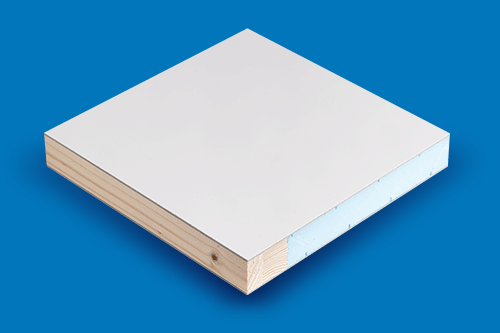

SANDWICH PANEL

- XPS insulation

- wooden frame

- external fiberglass finish

ceiling SANDWICH PANEL

- XPS insulation

- wooden frame

- external PVC finish

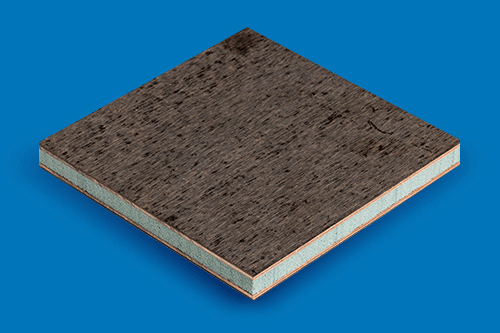

SANDWICH PANEL

- PET insulation

- rough phenolic laminate external finish

- Okoumé inner finish

SANDWICH PANEL

- XPS insulation

- black PVC reinforcements

- anti-slip fiberglass external finish

SANDWICH PANEL

- XPS RTM insulation

- extra-strong anti-break fiberglass (Extraglass) external finish

SANDWICH PANEL

- Okoumé core

- fiberglass laminated on both sides

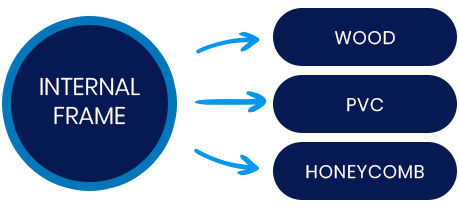

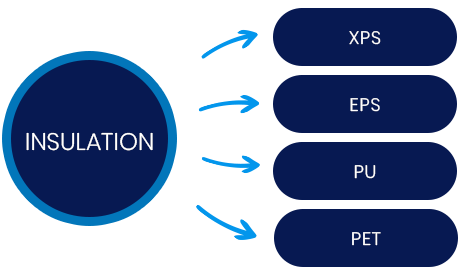

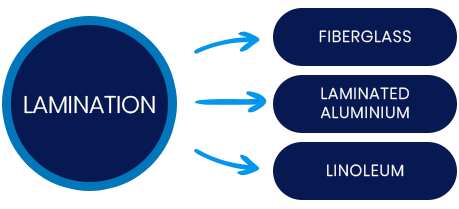

Customize your panel

Subcontract Manufacturing for RVs, Marine, and Mobile Homes

Palomar S.r.l. is highly specialized in accurate subcontract manufacturing, tailored to meet customers’ requirements where quality, strength, and customization are fundamental.

Our machinery includes ten CNC machining centers of various sizes, all equipped with state-of-the-art Industry 4.0 technologies. These advanced systems enable us to produce complex panels and structures with exceptional precision, strictly following our clients’ technical specifications. This allows us to manufacture lightweight, functional, and tailor-made components — ideal for space-sensitive environments such as campers, boats, and mobile homes.

Regarding bonding and lamination processes, we offer a wide range of technologies that ensure maximum hold, consistency, and durability. Our lines include polyurethane adhesives (both bead and spray application), as well as reactive hot melt and vinyl-based solutions. These technologies guarantee a stable and uniform assembly, capable of withstanding the stresses of mobile use and challenging environmental conditions like humidity and thermal variations.

Certifications and Environmental Sustainability

Certifications

We ensure safe working environments in full compliance with international safety standards ISO 9001 and ISO 14000, with a strong focus on accident prevention within our production areas.

Sustainability - Circular Resource Management

At Palomar Srl, we believe in responsible manufacturing that respects the environment and minimizes waste. Our goal is to build an increasingly sustainable production cycle, based on reuse and circularity principles. Since 2022, we have installed 2,000 sqm of photovoltaic panels on our facilities, significantly reducing the energy impact of our operations and final products. Sustainability is not just a commitment for us – it is a core value that shapes our company’s development every day. In 2023, we published our first Sustainability Report and obtained the Environmental Protection Certification.